Pre-Engineered Buildings (PEB): The Smart Future of Construction

Pre-Engineered Buildings (PEB): The Smart Future of Construction

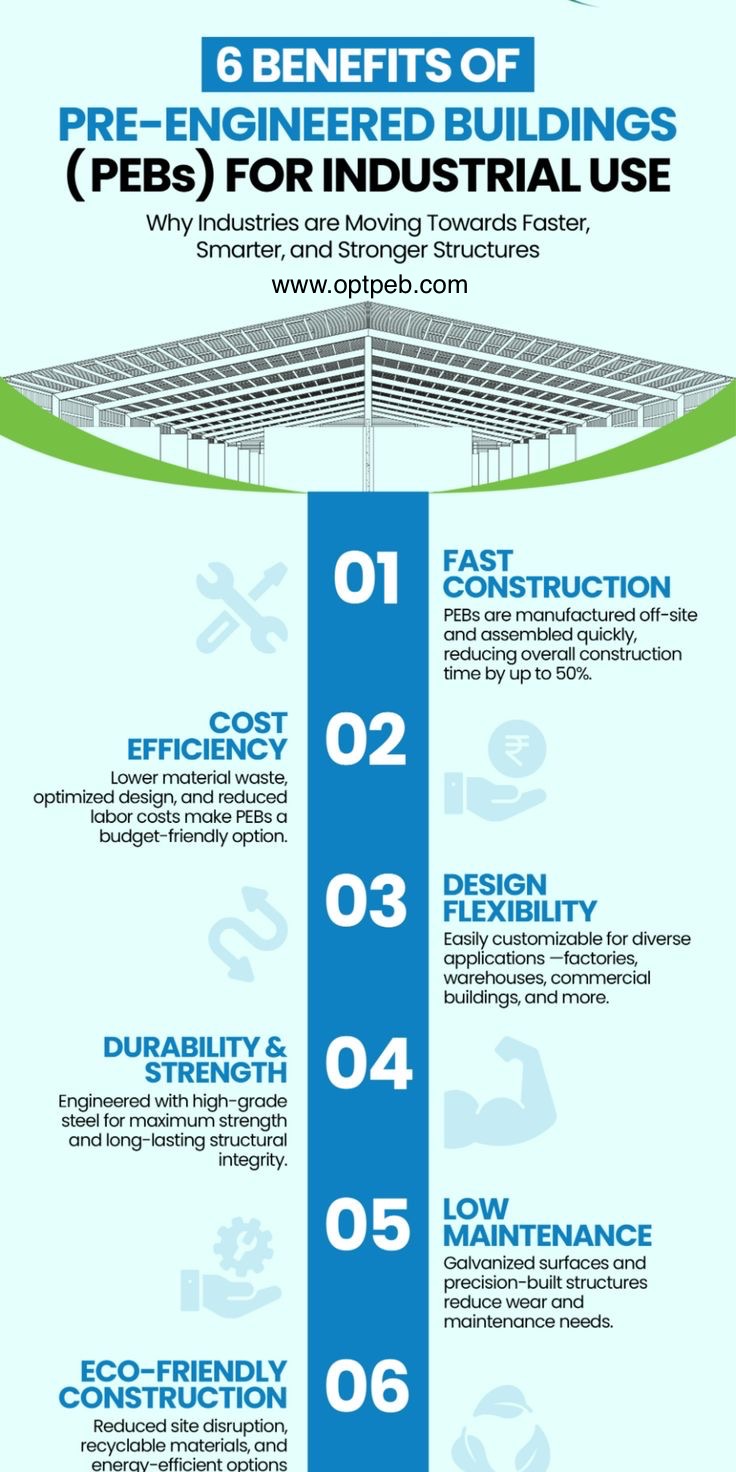

In today’s fast-paced world, businesses and industries are looking for faster, stronger, and more cost-effective construction solutions. This is where Pre-Engineered Buildings (PEB) have transformed the way modern infrastructure is built.

OptPEB, a leading name in India’s steel building industry, offers world-class PEB solutions designed to deliver strength, speed, sustainability, and savings — all in one structure.

What is a Pre-Engineered Building (PEB)?

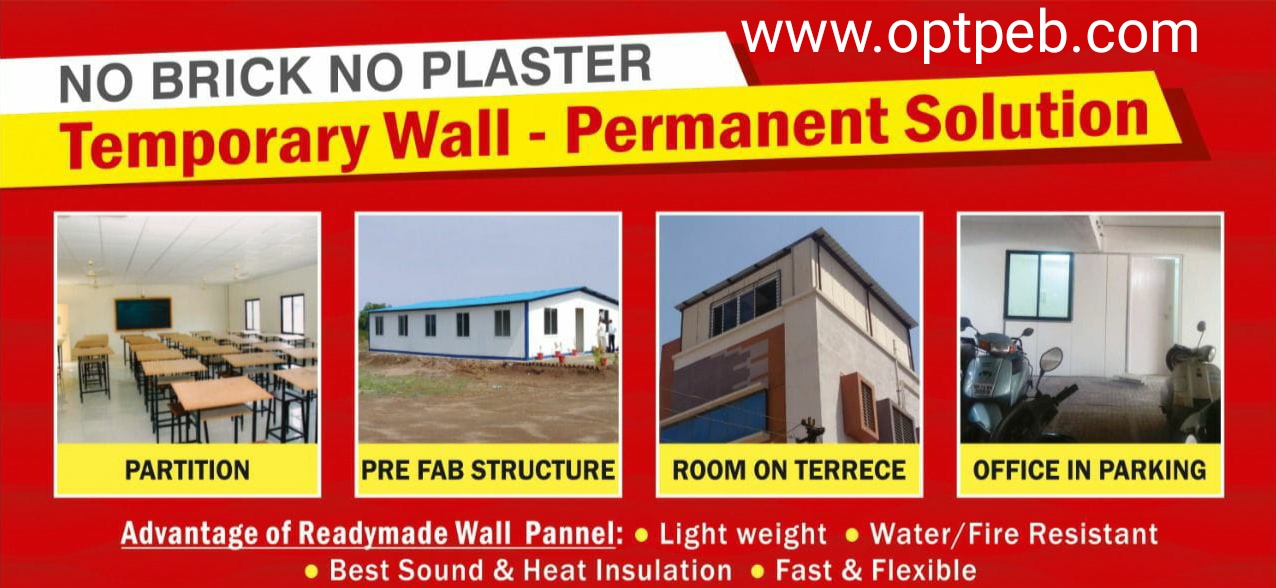

A Pre-Engineered Building is a steel structure designed, fabricated, and manufactured in a factory-controlled environment, then transported to the site for quick assembly. Each component — from the primary steel frames to wall cladding and roofing — is custom-engineered to meet specific design requirements.

Unlike traditional buildings, which are constructed entirely on-site using brick and concrete, PEBs are pre-fabricated and bolted together on-site, saving significant time and cost.

⚙️ Key Components of a PEB Structure

Primary Frame:

Built using rigid steel frames (columns and rafters) to bear the main load.

Secondary Members:

Purlins, girts, and eave struts that provide additional support to walls and roofs.

Roof and Wall Panels:

Made from high-quality steel sheets or insulated panels that enhance durability.

Bracings and Fasteners:

Used to maintain stability, alignment, and overall structural integrity.

Accessories:

Doors, windows, ventilators, skylights, and gutters customized as per requirement.

Advantages of Pre-Engineered Buildings

⚡ Fast Construction:

PEBs can be constructed 50–60% faster than conventional buildings since components are pre-fabricated and ready to install.

Cost-Effective:

Reduced construction time, labor costs, and material wastage make PEBs an economical solution for industrial and commercial projects.

High Strength & Durability:

Made from high-tensile steel, PEBs can withstand heavy loads, earthquakes, and extreme weather conditions.

Eco-Friendly Construction:

Steel is recyclable, and the PEB process minimizes on-site pollution and material waste, supporting green building initiatives.

Flexible Design & Expandability:

PEBs can easily be expanded or modified, making them ideal for growing businesses.

Aesthetic Appeal:

With modern cladding, colors, and architectural finishes, PEBs offer a sleek, professional appearance.

Applications of PEB Structures

PEBs are widely used across industrial, commercial, and institutional sectors, including:

Industrial sheds and factories

Warehouses and logistics centers

Commercial complexes

Aircraft hangars

Cold storage units

Metro stations, showrooms, and workshops

Schools, auditoriums, and hospitals

Why Choose OptPEB for Pre-Engineered Buildings?

OptPEB is one of India’s most trusted brands in the steel building industry. We specialize in designing, manufacturing, and installing PEBs tailored to customer needs.

Our team ensures:

Advanced engineering design using international standards

High-quality steel with long life and low maintenance

On-time delivery and installation

Custom-built solutions for industrial, commercial, and institutional projects

With OptPEB, you don’t just build a structure — you build efficiency, strength, and sustainability.

Conclusion

Pre-Engineered Buildings are the future of smart infrastructure — offering unmatched speed, quality, and versatility. Whether you need a large warehouse, a small factory, or a commercial setup, PEBs by OptPEB provide the perfect combination of performance and value.

OptPEB – Building the Nation with Strength, Speed & Sustainability.

https://www.optpeb.com